See what I found... Looking inside Ngahue IV

The Boat's Electronics

When, in 2016, we bought our HR53 in Kiel (Germany) as Tabaluga, we found that she had an interesting though quite eclectic collection of (very) old and (relatively) new electronics on board. On the one hand, she still sported her 1995 Furuno analogue radar that took in excess of 4 minutes to warm up (not exactly useful for quickly checking up on an Atlantic squall racing in your direction). Yet on the other hand, there was a quasi-professional Class A Comar CSA-300 AIS system linked to a reasonably modern and pretty big Garmin plotter located in the cockpit. There was also a semi-professional Thrane & Thrane VHF... (the handset in the cockpit was broken, as we discovered later - carefully not mentioned by the seller. Its replacement a year or so later also broke, after which we replaced the whole set with something more modern, even if less professional - see below).

We decided that for Ngahue IV we would need to seriously rationalise all this equipment. We wanted to choose a robust manufacturer, have adequate "reserves" in our electronic systems, and have instruments that were reliable and would always work. After a lengthy discussion at the 2016 BOOT Düsseldorf boatshow with Mr Sirko Feldbinder of Mare Multimedia, we opted for a new and complete set of Furuno instruments. For our departure in 2017 only one or two of the really good existing instruments on board were kept.

After our experience acqurired during our first two circumnavigation attempts, we decided to slowly remove all Furuno gear from the boat and settle on Raymarine as our single provider. Given the cost of modern navigation equipment, this transition will be carried out over several years... Some Furuno material has a strong reputation, notably their radar units - so this will probably stay. 2025 has been set aside to replace the navigation instruments (swapping out the Furuno FI-70s for Raymarine's i70S series. Last to go will be the Multi-function Displays because they are expensive to replace and we would want the most recent Raymarine models for our next spate of blue-water sailing.

In preparing for our first attempt at a circumnavigation, we ended up with the following, mainly

Furuno material on board:

![]()

> 2x Furuno TZTL 12F multi-function plotter displays: one in the cockpit and one at the inboard chart table (after ±7 years of use the touchscreens have become exceedingly difficult to operate)

> 5x Furuno FI-70 multi-function instrument displays: 4 over the main hatch and 1 at the inboard chart table

> Furuno GP-33 Navigator GPS set as a back-up to the GPS sets incorporated in the Furuno plotters and the Comar AIS

> Furuno open array solid state scanner DRS6A X-Class - the latest generation scanner when lauched in 2016

> Furuno Navpilot 711C with 2 control points (steering pedestal & chart table) operating a Simrad-Robertson hydraulic drive - our experience with this unit was totally RUBBISH!! It was replaced by a couple of decent Raymarine units two years later - see more below

> Raymarine Autopilot Controller ST 6002/SG3 Course Computer & Smartpilot (handheld remote steering device) operating a Lewmar Mambadrive (1/4 HP) - this back-up autopilot was also replaced/upgraded at the same time that we ditched the Furuno unit - see below. The Mamba drive too suffered "issues" and needed to be repaired at the factory before becoming (more) reliable.

> Raymarine (Autohelm) backup depth meter from 1995 displayed over an ST50 MULTI display (this unit seems quite indestructible!)

> Comar CSA 300 Class A AIS, which broke down but could be repaired in the Canary Islands in October 2019. We bought a Raymarine a700 Class B transceiver as reserve just in case the Comar breaks down again and this unit was actively fitted in April 2021. We found out that our new Simrad VHF set also has back-up AIS functionalities and was actually providing the AIS data for our Furuno TZTL screens when the Comar stopped transmitting (unbeknown to us). Comar these days refers to its CSA 300 unit as a legacy product - quite charming, really but not terribly satisfying when you have a unit on board!

After 26 years of using Raymarine equipment on the Ngahues I to III, we had great difficulty to get used to the "Furuno way of thinking" on the new instruments installed on Ngahue IV. It was only after much reading of the manuals that we have, with time, become slightly better acquainted with our new electronics (although there are still regular and quick panic-dashes to the instruction books to find how to perform some function that wedon't use regularly as with Furuno NOTHING IS LOGICAL or INTUITIVE, in our view). Another thing we discovered, but Furuno claims it is not their fault, is that the electronic Time-Zero charts we now use don't seem as good as the Navionics ones we had in our previous Raymarine C90W plotters on the HR37 & 43. Charts in the Furuno plotters "jump" on the seams between two areas that were put together, and during our first (2016) summer cruise we sailed twice by the Calshot Spit float in The Solent - a major navigational mark there - and did not see it on our e-chart!!! We took pictures of this incident and queried our mapmakers, who nodded and admitted that they get their chart material from C-Maps. And if C-Maps isn't correct, then our Mapmedia charts for the Furuno can't be correct either. It does make you wonder what was scanned and - more importantly - what wasn't... And why the same marks DO show up on Raymarine equipment that we have since 2021 added in parallel to the Furuno MFDs... Passing Calshot Spit again in 2018, we noticed a minor improvement: at least the buoy's name appeared on the plotter, even if the buoy itself as a symbol still didn't!!! In 2022 this situation hadn't improved!!! Perhaps the buoy is sulking with us??!! Pictured here is the boat's navigation corner over various refits... It is getting quite busy in the nav area with all the new gear now installed, including the ICOM M-802 SSB and a Raymarine Elements 7 plotter with its own charts and used as a back-up display and as a screen for the Raymarine B class AIS. In August 2018, we removed a Fastnet 55 Radio receiver and a Furuno weatherfax machine situated on the wall behind the navigator's seat and used the place to put our Iridium phone handset. The original place for the Iridium handset was in August 2018 taken up by the ICOM SSB.

New legislation enterring into force on 1st January 2023 (and which needed to be complied with by 31st December 2023) obliges users of VHF sets to disable a number of the 'old' channels and add a new one. Our Simrad fixed VHF set and our ICOM h/h VHF have both been sent off for these modifications a job easily done in modern sets as one just needs to reprogramme part of the software. Two of our older h/h VHF sets weren't worth updating and were removed from the boat before the end of 2023 when their presence and use became 'illegal'. Apparently, Belgium it was said would be quite strict in applying the new rules to all VHF sets; the Netherlands appeared to be more relaxed about them, requiring only newly sold sets to comply...

|

|

|

When we set out in 2017 for our first attempt at a circumnavigation, the boat's navigational electronics were fully up to date. Surprisingly though, in 2017, before we left, the Furuno wind instrument broke down, and needed to be replaced under guarantee (with a lot of dark mutterings from the Furuno engineer...). The radar recommended by Sirko Feldbinder did give wonderfully crisp and sharp images in Belgium, and would have shown up squalls at a good distance had it continued to function throughout 2017. Unfortunately, it didn't, and on our first Atlantic crossing, probably because of a loose connection (??), we were deprived of its joys and use! Chronologically explained, the other issues we encountered with our Furuno instruments were:

> software bugs with the wind instrument (it never gave the correct Beaufort scale number with the prevailing wind speed - this was remedied thanks to a software update in June 2019);

> as already mentioned the wind mast-head sensor breaking down after a few months use;

> the log/depth sounder transducer from Airmar broke down after 22 months and stopped working altogether as we picked our way into Bermuda (where there are lots of dangerous reefs and hidden rocks! After a LOT of pestering, we received a replacement unit from Furuno);

> another software bug with the log/odometer (it doesn't go beyond 999* miles! An issue we thought was remedied in June 2019 but it returned again in March 2020 when we again hit the 10.000M mark again. However, it now displays *999M, which is of course a GREAT IMPROVEMENT;

> the active aerial for the Navtex not giving any usable signal! (Oh well, we now use the RR aerial in the mast for this now);

> the software in the GP33 Navigator contained a flaw so that from early 2022 onwards to returned to a date in 2000. We sent the set back to Mr. Feldbinder of Mare Media for updating. Interestingly enough, the actual GPS position was not affected by the software issue; just the date. The only thing one noticed on the plotters was that tidal streams didn't correspond to 2022 reality (they were indicating streams back in 2000).

> the heading sensor giving the ship's direction has gone off by 5-10°, which also affects the heading of our radar image (real targets and their AIS position do not align)

All of this is hardly an advertisement for Furuno reliability...to say nothing of their (in our case at least) very miserable customer service! In July 2019, Mr Feldbinder, our German "Mr Electronics" spent 6 hours updating the software on our two plotters and the five FI70 instruments. They were then brought up to the latest level of software, and many (all?) of the bugs we experienced between 2016 and 2018 should have been resolved. Should... but in actual fact were not :-(!!! We certainly hoped so, if only out of respect for all the trouble that Mr Feldbinder had put into performing this update. Not the easiest of tasks... BUT, the updated instruments have since shown new bugs so that our Raymarine autopilots were constantly protesting at the strange data-input they get from the updated Furuno instruments (there were no bugs before the software update in late 2018, so it was quite easy to isolate the source of the issue!!). While we were brooding on a solution, it was recommended to just disconnect the "bridge" between the Furuno instruments and the Raymarine autopilots!

Steering, autopilots - and their saga

We always wanted Ngahue IV to have two full and COMPLETELY SEPARATE autopilots in case one should break down. Both actually broke down en route to Lanzarote in the summer of 2017!

When we bought the boat, she only had a single Raymarine SG3 course computer that steered the boat through a couple of Simrad-Robertson hydraulic rams (linear drives) configured in push-pull mode on the rudder quadrant. For our second autopilot we were advised to install a new Furuno course computer which was to drive a Lewmar 1/4HP Mamba drive. The Mamba drive simply bolts on to the Whitlock steering system where it bolts onto a splined shaft of the junction box that is situated in the engine room. That is a pretty standard set-up for many bigger Hallberg-Rassies. Unfortunately, the Mamba drive couldn't be delivered on time for the April 2016 refit (shame on Lewmar!), so as a stop-gap measure, the new Furuno course computer was temporarily linked to the Simrad-Robertson hydraulic linear drives (which - we were told - are immensely powerful).

It took the Furuno course computer quite some time to "learn" about the boat and initially the wheel in the cockpit swung madly (and even dangerously) from left to right while the Furuno unit was learning about the adjustments needed to steer the boat!! We fitted a set of bungee cords to limit the swinging movement of the wheel.

The Mamba drive, when it finally arrived, was connected with the Furuno, as we had originally planned. But it quickly generated several

'fatal error' messages and needed to be reset. The Furuno was then re-connected to the Simrad Robertson hydraulic drives, and the wildly

swinging steering wheel resumed.

In order to keep the swinging under control again, we fitted a couple of bungee cords (see photo), which seemed to work quite well, even if

it was a bit of a strange set-up for such a modern and hi-tech installation. Several months later, though, the Furuno had "auto-learned"

enough for us to remove the bungee cords... The Mamba (see more below) was subsequently linked to the old Raymarine course computer and

relegated to secondary or back-up autopilot

After many testing sessions and a few extra repairs, we seemed, by the time of the first departure for our circumnavigation in the summer of 2017, to have found most of the needed and acceptable settings on the Furuno whereby the Simrad-Robertson hydraulic drives no longer swung the wheel too wildly from port to starboard (the bungee cords were stored in the cockpit locker), and the Mamba drive didn't feed electro-magnetic information back to the course computer which then went into "fail" mode... Before leaving in 2017, unfortunately, we never got round to properly testing our auto-pilot drives for long-term reliability. We were quite dismayed, therefore, that during our trip down to the Canary Islands one autopilot after the other failed in mid-sea. Actually, this was a salutary experience as we were obliged to have to hand steer our boat for nearly two full days. Thus we discovered that: a) it could be done quite easily; and b) it was not as exhausting as we had feared. In fact, our boat steers very nicely and very lightly indeed. Bravo to German Frers for his design and Hallberg-Rassy for their sailing qualities!

When the boat was in Lanzarote, we reviewed both autopilots critically and ordered plenty of new and back-up spare parts for them so as to

avoid repeats! Some issues remained, and the Simrad Robertson hydraulics again broke a connecting pin near Bonaire in the Caribbean! Continuing our

circumnavigation double handed and entering the Pacific, we felt that we needed 2 fully operational autopilots that we could trust 100%. The upshot

of our deliberations was that this was yet another factor that contributed towards our decision to return to Europe to look into this and correct

a number of other issues that we had with the boat...

When the boat was in Lanzarote, we reviewed both autopilots critically and ordered plenty of new and back-up spare parts for them so as to

avoid repeats! Some issues remained, and the Simrad Robertson hydraulics again broke a connecting pin near Bonaire in the Caribbean! Continuing our

circumnavigation double handed and entering the Pacific, we felt that we needed 2 fully operational autopilots that we could trust 100%. The upshot

of our deliberations was that this was yet another factor that contributed towards our decision to return to Europe to look into this and correct

a number of other issues that we had with the boat...

On our way back to Holland, we stopped over in Swanwick marina in August 2018, where we had both old Autopilots removed and replaced with a pair

of new Raymarine Evolution EV-400 Autopilots. These steer the boat quietly, confidently and ever so gently! Our boat

electronics people, Maricom who are based at Swanwick marina, installed these two completely separate and

independent autopilot systems: Autopilot-1 and Autopilot-2. N° 1 is our main pilot as it uses the Simrad-Robertson hydraulic drives; N° 2 uses

the Mamba drive to steer the boat. You switch from one pilot to the other with a simple switch on the steering pedestal. There is a 5 second

delay as screen of one pilot goes off and the other pilot comes on line. All power is removed from one drive and transferred to the other drive

unit and for the pilot to come on line. Both pilots already generate a lot of their own data, and receive some extra navigational data from the

remaining Furuno equipment via two pretty complicated-looking, but apparently quite simple data "bridges". Compared to the Furuno information

displayed, there is just one line now missing on the plotter, namely the current fixed heading line; you do retain, as with the Furuno pilot,

the general heading of the boat as corrected and adapted all the time by the autopilot. Perhaps in close coastal sailing one would want the peace

of mind offered by that straight line of the fixed heading. That was the happy situation in August & September 2018 - unfortunately, it wouldn't

last.

On our way back to Holland, we stopped over in Swanwick marina in August 2018, where we had both old Autopilots removed and replaced with a pair

of new Raymarine Evolution EV-400 Autopilots. These steer the boat quietly, confidently and ever so gently! Our boat

electronics people, Maricom who are based at Swanwick marina, installed these two completely separate and

independent autopilot systems: Autopilot-1 and Autopilot-2. N° 1 is our main pilot as it uses the Simrad-Robertson hydraulic drives; N° 2 uses

the Mamba drive to steer the boat. You switch from one pilot to the other with a simple switch on the steering pedestal. There is a 5 second

delay as screen of one pilot goes off and the other pilot comes on line. All power is removed from one drive and transferred to the other drive

unit and for the pilot to come on line. Both pilots already generate a lot of their own data, and receive some extra navigational data from the

remaining Furuno equipment via two pretty complicated-looking, but apparently quite simple data "bridges". Compared to the Furuno information

displayed, there is just one line now missing on the plotter, namely the current fixed heading line; you do retain, as with the Furuno pilot,

the general heading of the boat as corrected and adapted all the time by the autopilot. Perhaps in close coastal sailing one would want the peace

of mind offered by that straight line of the fixed heading. That was the happy situation in August & September 2018 - unfortunately, it wouldn't

last.

Just before our second departure for our circumnavigation in July 2019, Mr Feldbinder, our "Mr Furuno", came on board and updated our Furuno software. No sooner had he left, and we started experiencing new problems with our Raymarine autopilots. Despite best efforts from Raymarine Spain (not Furuno) we found that the only way to stop our auto-pilots from being 'alarmed' all the time was to disconnect the data "bridges". A new data bridge was installed by Maricom in early 2021 (Raymarine Spain actually admitted in Las Palmas that their proprietary bridges weren't very good!!!). As a note aside, actually, even without wind and water speed input, the Raymarine autopilots demonstrated that they could perform VERY WELL on their own under nearly all circumstances. They just proved to be a little twitchy when a series of following waves throw the boat around! We are hoping a complete return to quiet steering of the boats when we install a set of new navigational instruments from Raymarine in 2025!

There are control units for the Raymarine autopilots fitted at the steering pedestal and at the inside chart-table. We also have a Smartpilot remote controller that will operate whichever pilot is active at the time. It sits in your hand and allows full steering from where you are on board. Its base station has been moved from the aft cabin to the walkthrough ceiling as the handset sometimes lost its connection with the base station in its old position (the main course computers have been installed in the aft cabin under the port sofa that we have there)..

Summarising our autopilot experience therefore -> Based on our sailing in August & September 2018, the new Raymarine system worked perfectly, and our stress levels returned to normal - the way it should be! UNFORTUNATELY, in May 2019, Mr Feldbinder of mare-Multimedia who had installed all the Furuno equipment visited us in Bruinisse and updated all the software on the Furuno plotters and the Furuno instruments. Rats, the perfect chatter between Raymarine and Furuno via our "bridge" was disrupted by regular "No pilot" alarms appearing on the Raymarine screens. When it comes to "software", finding the error is impossible for the lay sailor! Our conclusion is that Furuno Autopilots are not made for (our) sailing boat(s); Raymarine autopilots are. Furuno makes good radars, although the latest Raymarine units certainly give Furuno a run for their money. For other navigational equipment, any brand will do. Perhaps it was just our bad luck, but EVERY individual Furuno instrument on board has broken down or displayed one or several quite severe faults: log, odometer, depth, wind instrument, water thermometer, Navtex. Even the plastic holder of the GPS aerial manages to rust! Our experience with Furuno Customer service has been quite appalling too... The company simply ignores you and hopes you will go away, or promises to do something which then never materialises either. In short, WE ARE NO FURUNO FANS!!! Our frustration with Furuno increased again because as a result of updating the software in our instruments, the seamless communication between Raymarine and Furuno in August 2018 disappeared in June 2019!!!

In 1995, Hallberg-Rassy fitted out our boat with a Whitlock steering system. That was a long time ago, and the Whitlock brand/company has since been bought up by Lewmar. Unfortunately, information on early steering systems is very hard to come by, as are the people who know something about them. The documentation that was supplied with our boat was in part irrelevant, and on several points quite unclear as to what should be done to the system… After some trawling on Internet, we found Cliff Mogridge of Whitlock steering who proved to be helpful with designs and information on our steering system. Cliff used to work for Whitlock and Lewmar. Unfortunately, he never responded to our fervent request that he come on the boat during 2018 summer to look at, and service our steering. A pity, especially as we know a few other HR owners who have had him on board! And he knows his business! Mechanically speaking, Whitlock systems are pretty simple and extremely robust. They do require regular maintenance, but can take large amounts of abuse before actually failing. The various components are: the steering wheel, the pedestal mechanism and a gearbox; a bevel-head and gearbox in the engine room (this box also has a splined shaft sticking out which allows you to simply fit the 24 Volt 1/4-HP Mamba drive on to), and a draglink just next to the rudder quadrant. These components are inter-connected with solid stainless steel rods and two sets of universal joints to get round angles in the engine room and under the aft-cabin bed. In the end it was Yachtservice Van Swaay that did the maintenance on the system and, reassuringly, found no traces of excessive wear in the bevel-heads or gear boxes after 27 years of use. In 2025, we did a fairly comprehensive maintenance of the whole steering system, starting with the junction box inside the steering pedestal and ending with the draglinks under the berth in the aft cabin. Aqualift in Nieuwpoort was extremely helpful, working together with us to check out and service all the parts of the system!

A word should be said here about Mr Dirk Roegiest of Deurne. Thanks to a contact at the Belgian Boat Show (which is usually held each year in Ghent in February), we were given his contact details as the man who could sort out our breaking connector pins between the Simrad Robertson drives and the rudder quadrant. Mr Roegiest provided us with a wealth of information and advice and we left him with the bronze rudder fitting to which the Simrad-Robertson drives are connected. He machined down the outer end of the fitting (which had become damaged by the previous breakages, drilled out the 12mm holes for a couple of 14mm ones. And he made up a new set of strengthened and hardened connector pins. When you look at the photo, you'll find it hard to spot many differences with how things were. But the whole set-up is now definitely much stronger. Mr Roegiest's work has seen us cross the Atlantic and half-way across the Pacific; and not a single nut was loose or showed any play. (see photo above)! In Spring 2022 a pin did break off again in a wildly following sea and took minutes to replace<; just to be sure I ordered a couple of extra pins from Mr Roegiest, who still remembered me and the boat from 2018/19: excellent customer relations!

Communications

Under previous ownership, communication equipment on board Ngahue IV had been put together rather haphazardly. In August 2018, we decided to modernise things, and the list of equipment currently on board looks as follows:

> A SIMRAD RS35 DSC VHF with integrated Class B AIS receiver unit as our principal VHF - situated at the chart table, with a wireless extra handset for use in the cockpit (this was installed in August 2018). The unit backs up our Comar AIS Class A system as well as the Raymarine a700 AIS Class B system.

> There are three hand-held VHF sets: ICOM MC73-Euro - Raymarine 101 plus a 3rd Brand X yellow h/h VHF as our grab-bag backup. In 2022/23, the Simrad and ICOM units were updated to reflect the different new VHF channels in use in Europe.

>  An ICOM IC M-802 SSB with an ICOM AT-141 tuner Single Side-band (SSB) unit, connected to a Pactor modem p4 DR7400 also installed in

August 2018 to complete our long-range communication systems - a "Giant Dynaplate" installed under the port quarter of the hull

makes for the adequate grounding of the SSB. Pictured here is just the equipment needed to install the SSB set itself; we managed to find

spaces for everything (see pictures of chart table area above). The unit gives good reception and transmission, as we experienced during our daily

World ARC SSB-net chatter sessions. Thanks to our Sailmail subscription we can send and receive e-mails worldwide.

An ICOM IC M-802 SSB with an ICOM AT-141 tuner Single Side-band (SSB) unit, connected to a Pactor modem p4 DR7400 also installed in

August 2018 to complete our long-range communication systems - a "Giant Dynaplate" installed under the port quarter of the hull

makes for the adequate grounding of the SSB. Pictured here is just the equipment needed to install the SSB set itself; we managed to find

spaces for everything (see pictures of chart table area above). The unit gives good reception and transmission, as we experienced during our daily

World ARC SSB-net chatter sessions. Thanks to our Sailmail subscription we can send and receive e-mails worldwide.

> Our main AIS equipment is a Comar 300 Class A unit - this semi-professional unit allows us to send out our own messages and information and is

eminently visible! On our World ARC, other boats often used us as a marker beacon because we were visible for some 60 Miles and more!!! Furthermore, we

have a Raymarine a700 Class B transceiver as a second, fully-operational backup system. Both AIS systems can be used separately. From 2025 the Comar

unit will be replaced by a Raymarine 4000 Class A transceiver.

> A Furuno NX-300 modern Navtex receiver with its own aerial, but it is currently linked to our RR Mast-head aerial for long-range communication (using its the supplied Furuno aerial gave the most appalling results!)

> A Sea-Me active radar transponder on our radar pole (which seems to have reached its useful end of life and looks like needing to be replaced; the cost for a new set is quite high, so for the time being the old set remains in situ) & an Echo-Max passive radar reflector in the mast

> Iridium Pilot satellite phone (or IOP - Iridium Open Port) and Internet communication unit, with an on-board Netgear WiFi hub

which links this external communication with our computers & iPad. We have two dedicated laptops (an HP Pavilion and a Durabook laptop), both

specifically suited and programmed for our communication needs. One has a solid state hard disk, operates under Windows 7, and has all

possible automatic downloads switched off to minimise the risk of unwanted downloads at costly Iridium dollars. The other is a "doctored"

laptop that operates on Windows 10 (we've had this one "throttled" and "muzzled" so that it doesn't - unless given express permission -

chatter with the world via Iridium at $10 per Mb) and offers nearly a Terabyte of hard disk space. It has been specially protected to

conform to quasi-military standards of robustness; it withstands humidity and can be dropped up to 1 metre!

Our Iridium air time provider is the AST Group. At one point we were inadvertently let down by them when

they cut off our SIM card in mid-Atlantic in November 2017, apparently because a programme called Google Marketplace (we didn't even know this

programme existed) had downloaded multiple tens of Megabytes and exceeded our monthly quotum several times over! We have established new and

better rules with AST so as to avoid such a thing happening again, as we felt it was completely unacceptable to be left without any communication

with the outside world for more than a fortnight on an ocean crossing! No meteorological information, no medical communications, no chats to family

who were worried sick! We had a second run-in with AST in Tortola, where we spent a lot of time on the phone with them, as we were experiencing

difficulties with the "voice" side of our Iridium. Probably the only problem was that after the hurricanes of 2017, the telecom companies in

Tortola were heavily using very powerful satellite communications as most land lines were dead and that these were interfering with our much

weaker Iridium signals. Once out of BVI, our Iridium Pilot set was working perfectly again! AST, who had at a distance determined that our aerial

was definitively defective and no longer under guarantee because of a faulty installation, concluded, after full testing later in the UK, that

the aerial was perfectly OK! Surprise, surprise... We did follow their requirements and have adapted the set-up of our aerials at the back of

the boat and the Iridium aerial now sits higher than anything else, including our radar. AST now reckons that our installation is fine; the

Iridium has certainly been working okay ever since. So I guess that makes us contented AST customers these days. In all their correspondence,

they refer to us as Dear Valued Customer, which definitely has a nice ring to it!

As technology advances, we will probably remove all our Iridium equipment and replace it with a Starlink system at some stage in the future... Watch this space, as they say. At the time of writing (2024/25) we are in between moments of blue water cruising - consequently, we have suspended our AST subscription.

> As an Iridium back-up we have an additional Iridium 9555 h/h phone with air time bought from another service provider, so that we are not dependent on AST and the IOP alone!

> We also have a Yellow Brick Y/B tracker Pro, which not only transmits our position, but can also be used for Text messaging and simple e-mails (and even short updates on the boat's Facebook page, though this latter service has been suspended - we had hoped temporarily, but apparently not...)

> A couple of Sony SSB & Worldband radio receivers are on board as well as a Blaupunkt radio/CD-player in the saloon which enable us to pick up a multitude of (analogue) radio stations around the world and provide on-board musical entertainment

The radio, television & Navtex equipment are all connected to our very sophisticated RR Pacific aerial in the mast; the many 'boxes' with the antenna's outputs near the chart table look very impressive and when we finally got our television connected to the TV-output, we were astonished by the plethora of signals that (still) came out there (signals need to be analogue though, as modern digital signals are not recognised). As you can't stop progress, and many countries have moved to digital television signals, we modernised our television and aerial in 2022. Our new on-board television and its antenna are now compatible with these latest signals. How long will our on-board (Blaupunkt car) radio remain operational??? We will need to think about a DAB replacement soon...

Electricity and 'Green Energy'

With an increasing number of electric and electronic accessories on board, it is imperative to have a decent-sized and reliable battery bank

on board, as well as the ability to generate enough electricity to quickly and efficiently charge those batteries. Ngahue IV has a

house bank of 6 Victron batteries (each unit is rated at 12V/220Ah and weighs 66kg) which together give 660Ah at 24 Volts in three groups of

24V/220Ah (total these 6 weigh ±400kg). In 2017 we started off with Victron AGM batteries for our house bank. When they were up for

replacement in 2023, we changed them to Victron GEL batteries which apparently have a longer lifespan and can be discharged more deeply than AGMs...

With an increasing number of electric and electronic accessories on board, it is imperative to have a decent-sized and reliable battery bank

on board, as well as the ability to generate enough electricity to quickly and efficiently charge those batteries. Ngahue IV has a

house bank of 6 Victron batteries (each unit is rated at 12V/220Ah and weighs 66kg) which together give 660Ah at 24 Volts in three groups of

24V/220Ah (total these 6 weigh ±400kg). In 2017 we started off with Victron AGM batteries for our house bank. When they were up for

replacement in 2023, we changed them to Victron GEL batteries which apparently have a longer lifespan and can be discharged more deeply than AGMs...

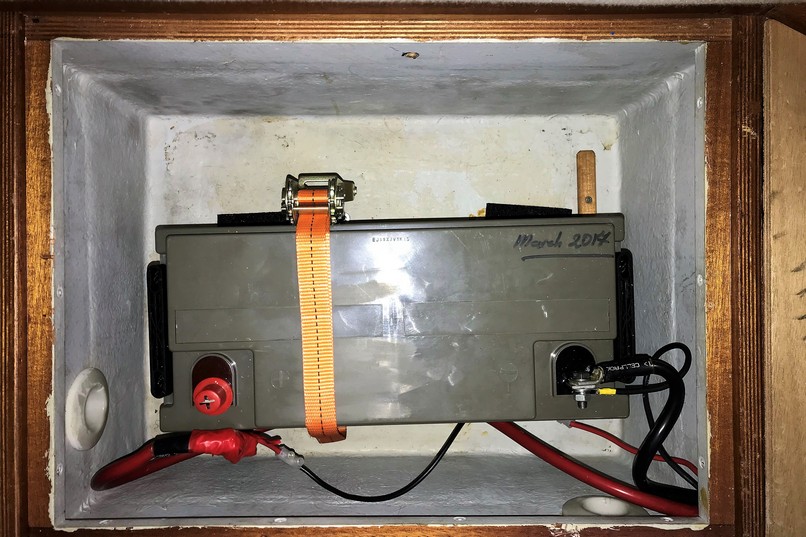

I'm afraid we're still very old-fashioned here and haven't gone down the Lithium route. Shown here 2 of the 4 GEL batteries that are installed at the base of the mast (2 others are installed in the aft cabin under the double berth - see further below. The new GEL units actually look exactly the same as the AGMs which was a bit of a disappointment when looking for a new "wow" factor when installed. Back in 2017, we managed to "cook" the two aft AGMs through over-charging during the 48 hours of motoring during our Biscay crossing! They had to be replaced in September 2017. We suspected a faulty regulator, which has since been replaced by a much better model (see below). In September 2017, we also added 3 battery switches and 3 Victron Argofet battery isolators. We are now able to isolate each of the battery groups and to charge or run them individually. Allowing for up to 50% of this capacity to be used before really harming these deep cycle GEL batteries, we have found that our battery bank requires recharging every two days or so. On our travels, we experienced only one situation in the Caribbean where we needed to take down our (then AGM) batteries to 54%; neither the batteries nor I really liked this. Four years later, in 2022, battery performance of the AGMs started diminishing, pointing the way to a new set of batteries being needed for 2023.

In addition to our normal shorepower charging ability, the boat has a set of two medium-sized Sunware SW20165 panels on deck as well as two flexible Solbian SP 125 & two SP 130 solar panels (making a total of 4 Solbian panels), controlled by a Victron Blue Solar 100/50 MPPT regulator. The Solbian panels are mounted on our bimini and all cables protected inside 'tunnels'. All our solar panels together should yield a maximum of some 600 watts of solar electricity in the tropics when the sun shines directly onto the panels (usually we clock up about 400-450 max). Furthermore, there is a Watt & Sea 600W water generator (the small Sunware panels are connected to the smart regulator that came with the Watt & Sea). The Solbians are connected to their own Victron smart MPPT regulator, which has a display showing exactly how much electricity they are producing. Finally, Ngahue IV has a very solid Westerbeke 6kW (230V) generator installed in 1995 by Hallberg-Rassy in the Engine room The photos show the psychedelic colours of the Watt & Sea regulator sited under the seating in the aft cabin, and the Westerbeke in its red soundshield.

|

|

|

When operating, the Westerbeke generator (pictured twice here, the middle photo as we found her in 2016; the right one is as she is at the moment - for instance the old black feed has disappeared) is quite silent outside the boat and only really audible in the cockpit (the sound insulation of the cockpit sole is quite thin). It is used mainly for feeding the watermaker and the washing machine with AC; these are the major 230V users and require significant quantities of power. Unfortunately, when the Yard installed the generator, they certainly did so in an aesthetically pleasing, but perhaps not totally practical manner... To explain, the cooling system often ended up with airlocks in it because of the long circuit that the cooling water needed to follow. Furthermore, the hose dipped down and came back up again, and offered ideal opportunities for forming incapacitating airlocks to form everywhere... In the 2018/19 winter lay-up, we had the cooling circuit relaid by Van Swaay Yachtservice in Bruinisse (which you can see if you look very carefully at the middle picture). The new circuit is considerably shorter and a dedicated seawater entry point with its own water filter pot just for the generator was added. Previously the generator shared a seacock & filter pot with the freezer, toilet and watermaker. Westerbeke doesn't disapprove of this, but suggests not sharing inlets with other users as it is not quite ideal. Well, that point has been remedied. The watermaker too was given its own inlet in 2021.

During the first Atlantic circuit part of our circumnavigation we had lots of problems with the generator (as everyone seems to have). This led

us to increasingly question the reliability of our Westerbeke (referred to as "Wester-break" by a charter company manager next to whom we were

moored at the time/Nanny Cay). We seriously considered completely replacing it with a modern Whispergen one... But a patient and conscientious

engineer in the BVI looked at the Westerbeke and found that previous maintenance had not been done properly, e.g. the seawater pump had been

mercilessly hammered and bolted into the engine block so that the pump axel and impeller were misaligned (see photo)

and led to early failure of our impellers. The exhaust elbow

also failed to allow for a free flow of cooling water into the exhaust system. All of this had been hidden by the fact that the cooling water of the

Westerbeke is normally - on our boat - directed BELOW the waterline. Although less friendly to the ear, we have now redirected the water flow through

the normal exhaust ABOVE the waterline, which allows you to see whether there is a clean flow of water coming out of the exhaust. Yes, this set-up

could lead to a pressure build-up in the exhaust, which isn't good. But the Westerbeke has a sufficiently big 3 cylinder diesel

engine for this not to be a problem. The new seawater pump and exhaust elbow have transformed our Westerbeke into a much more reliable machine.

Maricom recommended that we also install a Blue Sea Systems M2 1838 AC multi meter to electronically monitor the electricity produced, both by shore

power and more importantly by the generator. That way we can see immediately whether the electricity-generating side of the generator is operating

properly. We have stayed with our Westerbeke, which has worked faultlessly since. It's only done some 700 Hours, which for this type

of generator (generally designed for some 2000+ hours, apparently) is quite low, with lots of margin left.

and led to early failure of our impellers. The exhaust elbow

also failed to allow for a free flow of cooling water into the exhaust system. All of this had been hidden by the fact that the cooling water of the

Westerbeke is normally - on our boat - directed BELOW the waterline. Although less friendly to the ear, we have now redirected the water flow through

the normal exhaust ABOVE the waterline, which allows you to see whether there is a clean flow of water coming out of the exhaust. Yes, this set-up

could lead to a pressure build-up in the exhaust, which isn't good. But the Westerbeke has a sufficiently big 3 cylinder diesel

engine for this not to be a problem. The new seawater pump and exhaust elbow have transformed our Westerbeke into a much more reliable machine.

Maricom recommended that we also install a Blue Sea Systems M2 1838 AC multi meter to electronically monitor the electricity produced, both by shore

power and more importantly by the generator. That way we can see immediately whether the electricity-generating side of the generator is operating

properly. We have stayed with our Westerbeke, which has worked faultlessly since. It's only done some 700 Hours, which for this type

of generator (generally designed for some 2000+ hours, apparently) is quite low, with lots of margin left.

On the solar front, we started off having just two high-performance Solbian SP125 black contact flexible solar panels that we simply "velcroed" and zipped to the bimini. Whether the boat is at anchor or sailing, these two panels potentially generate 250-plus watts at 24V. We thought that this would be enough to cover our (mainly) refrigeration needs. Already in Belgium, on a sunny day, we found that they easily generated 150 watts; in the tropics, with careful positioning and on a sunny day, they reached approx 225 watts at midday. Our initial experience during the first departure on our circumnavigation showed that this output was a little inadequate. Therefore, we decided to add another two Solbian SP130 panels to generate a total of 450-500 watts from say 10 a.m. to 4 p.m. each day. When we doubled the number of solar panels, we of course also needed to upgrade the Victron regulator to their 100/50 model. We also discovered that we needed to adapt the wiring of the 4 panels as in series they started producing close to 100V: a bit too close to the operating limits of the Victron regulator. By connecting the 4 panels in parallel, the voltage drops to about 45V, and the overall power output reaches the hoped-for 450 watts quite easily. In addition, there are a further two fixed Sunware SW20165 CA-10/207 solar panels fitted to the deck, just before the cockpit windscreen. These are wired into the Watt & Sea regulator, which specifically allows for two inputs: one from the water generator and one from an extra 'green' source, in our case these two panels. These two panels do tend to get shadows on them from the boat's superstructure, so their output can drop significantly at times.

Regarding our hydro-generator, it is of the essence to keep the Watt & Sea well down in the water (at least a foot/30cm in the water), so that the propeller can achieve its full electric output. Unfortunately, the HR53 sugar scoop stern comes up quite a bit and despite having the 'long arm' version, our Watt & Sea often lifts out of the water, especially in moderate to rough seas and on a port tack. After our first Atlantic experience we decided to fit the larger 28cm propellor on our Watt & Sea in order to generate more electricity! Clearly though, the rated 600 watts is only generated by boats that sail much faster than we do and manage to keep the propeller well down in the water all the time. At a rough guess, I'd say our Watt & Sea delivers about a quarter to a third of its stated output when operating in downwind/tradewind sailing conditions (covering probably the fridge and/or freezer needs). In the Pacific trade winds, the boat was heeled over more favourably for the Watt & Sea. Several people we have spoke to all agree with us that the Watt & Sea is an interesting unit, but needs relatively high boat speeds to attain the output that is claimed for this unit!!! Obviously we need to sail faster, which we managed for example on a trip up the North Sea in 2022, when the Watt & Sea on its own managed to cover more than 90% of the boat's daily energy requirements...

Watt & Sea hydrogenerators are subjected to lots of pressures when dipped in the wild waves behind your boat. They pivot around to follow the boat's movements; but in doing this, the plastic bushes in the retaining brackets wear away. In 2022 we replaced these at a reasonably moderate cost; later we sent the whole unit back to the factory for a much-needed service. The system is good to go around the world again. In our collection of You Tube films, there's a short one on the Watt & Sea dancing around behind the boat when one of the retaining lines chafed through - we have since reinforced the line and insert a long screw through the Watt & Sea leg to keep the unit firmly down and in the water.

With regard to generating electricity with

the main engine, our Volvo-Penta TAMD 41B HD engine was retro-fitted in 2010 with an additional moderately high-output

24/100 Amp alternator. The old unit is still pictured here; it is an American Leece-Neville BSC3014U model (Leece-Neville, a Prestolite brand).

Unfortunately, under previous ownership, the alternator had been damaged by copious amounts of seawater dripping on it. When we had the unit

off the engine for a rebuild, it couldn't be safely reconditioned (too many internal bolts oxidized together). So we had it replaced altogether

by its successor model (which is a smart and mean-looking dark-black unit). The old unit could be serviced though (but not fully reconditioned

and rebuilt), and now has a place in the boat with the other spares on board. The new unit did - unfortunately - fail in autumn 2021 because of

a broken internal regulator.

With regard to generating electricity with

the main engine, our Volvo-Penta TAMD 41B HD engine was retro-fitted in 2010 with an additional moderately high-output

24/100 Amp alternator. The old unit is still pictured here; it is an American Leece-Neville BSC3014U model (Leece-Neville, a Prestolite brand).

Unfortunately, under previous ownership, the alternator had been damaged by copious amounts of seawater dripping on it. When we had the unit

off the engine for a rebuild, it couldn't be safely reconditioned (too many internal bolts oxidized together). So we had it replaced altogether

by its successor model (which is a smart and mean-looking dark-black unit). The old unit could be serviced though (but not fully reconditioned

and rebuilt), and now has a place in the boat with the other spares on board. The new unit did - unfortunately - fail in autumn 2021 because of

a broken internal regulator.

The High Output Alternator (HOA) is controlled by a totally up-to-date new Sterling Pro-C Digital high performance smart regulator (pictured

here - the red box under the ventilator) that our electronics suppliers Maricom installed in August 2018.

It certainly looks an impressive piece of kit fixed to the side of our engine room. We added the remote control panel for it outside the engine

room, which is especially useful to keep an eye on what the alternator is getting up to on longer stretches of motoring.

When we acquired Ngahue IV, we "inherited" the electrics as installed by the previous owner. This turned out to be nearly exclusively

equipment from the Victron company and specifically their blue energy product range. Our previous boats

had been equipped with Mastervolt material. So in addition to getting used to a different colour (blue instead of grey & green), I also needed to

adapt to a slightly different approach to energy management. ![]()

We have a:

> Victron Inverter 230V/2000W - the Phoenix model;

> Victron 24V/100 Amp battery charger - model Skylla TG (for the main battery bank - it started playing up in mid-2018 and needed to be replaced in 2019!);

> Victron 12V/25 Amp battery charger - model blue power (for the 12V, mainly engine starting battery bank); and

> Odelco Battery Control System DCC 40000 which monitors energy flowing to and from the house battery bank - there is also a Victron MPPT Controller instrument showing how many watts our solar panels are generating.

The inverter and generator outputs feed into the boat's wiring via a hefty selector switch (Off/Ship's batteries - Shore-power - Ship's Generator - Inverter; switch renewed in 2017) and thus allows the direct use of the washing machine, or the Aquatec watermaker which operate at 230V. Plus of course any electrical equipment that might be switched on at sea (e.g. vacuum-cleaner). Below you can see pictures of (from left to right) our Victron Battery charger, the Inverter and two of our 6 Victron AGM batteries - 12V/220Ah, that were unfortunately "cooked" by a malfunctioning regulator (still there from the previous owner, who thought the best place for the control panel and alarms was INSIDE the engine room instead out outside it, which I think had been Sterling's intention!) during two days of non-stop motoring. These are situated under the double bed in the aft cabin. In the second photo block underneath, you can see how we have nearly doubled the capacity of our 12 Volt circuit by a much better use of the available space in the battery box. We now have two 12V/110Ah AGM units instead of a single 12V/130Ah battery. In Spring 2025 we replaced these batteries by a new set - just to be sure that both engine and generator will start when you press the starter button.

As on our previous boats, a lot of thought has gone into reducing electricity consumption, e.g. through "LED-ifying" all light-bulbs, and rendering the fridge & freezer cooling systems more efficient. Careful thought has also gone into the boat's electronics, whole parts of which can be switched off whilst ocean sailing, thus conserving energy. With all equipment running, consumption whilst sailing will easily add up to 8-10 amps (at 24V), much of which is normally covered by renewables (= our Watt & Sea water generator and our Solbian solar panels). This isn't always the case (see above) because the water generator is not always deep enough in the water, and initially with only 2 Solbians we were mostly just under self-sufficiency. With about 300Ah truly available from the domestic batteries (on the total capacity of 660Ah - we don't like running them to below about 60-70%), charging cycles at sea are usually about once every other day or so (running the generator or the main engine is also useful to make some fresh and some hot water at the same time). When at anchor, our now extended to 6 solar panels (4 big ones/2 little ones) cover all our energy needs, certainly in the tropics.

Maintaining a cool temperature in the boat is achieved through keeping hatches open and relying on several Caframo ventilators installed around the boat in strategic places. For those people familiar with Renault's 1950s/60s Dauphine model (this was my first car), its instruction manual simply stated: "For ventilation, open the windows"!! We applied this kind of simplicity and deliberately stayed away from installing air-conditioning units because of the heavy energy drain they represent. And we certainly have no wish to run the generator much of the time just to keep cool...

To keep us safe from stray currents when plugged into shore-power, we have had a Mastervolt 6kVA isolation transformer complete with a Mastervolt soft-start unit fitted, which accepts 110 & 230 volt inputs. The soft-start unit is there to prevent our electricity-hungry boat from tripping all the fuses in a marina electrical system when initially plugged in... Apparently adapting the isolation transformer from its current setting 230V to 110V is very complicated. In Saint Lucia we bought a step-up tansformer to turn 110V into 230V. It's not a huge unit, so we only can keep the essential users plugged in when using it!

All our new electrical, communications and electronics that were fitted in May 2017 and again in August 2018 have been installed by Dave Cobb, Paul Olley and Mike (son of Dave) Cobb of Maricom. I was first introduced to Dave and Paul in October 2004 by the Hallberg-Rassy UK representative, and have been a happy and loyal customer ever since. Twice now, I have even asked them to come especially to the Netherlands and to Belgium respectively to work on our Ngahues (III & IV). They have a deep insight into what equipment is on the market, and what generally works and what generally breaks down. Their advice - which evolves with what is available on the market - is always to the point and completely neutral. We have systematically followed their advice and rarely been disappointed! A phone call or a text-message have sufficed to put matters right, even for things they had not installed. It's a shame for us that because of Brexit we can no longer use our U.K. supplier network these days; but we are building up a new network of good service providers for our boat in the Benelux...

Water & the Water-maker

As standard, Hallberg-Rassy 53s have a single

massive stainless steel water tank which holds ±1020ltr of water. It is situated under the floor in the forward part of the saloon. We found

that in an ocean swell, the tank moved around and made strange "boink"-like noises. During our 2018/19 winter refit, we had the tank fixed

in place with large wooden wedges. The "boink" is now significantly less. Hot water is/was (originally) provided by a 60 ltr calorifier, which

is heated either by the coolant fluid from the engine, or via a 230V/800W heating element. This tank developed an internal leak which resulted

in fresh water seeping into the Volvo-Penta cooling circuit (and causing the expansion tank to overflow!). This was spotted by the careful

eye of Dominique Fily, our VP engineer in Papeete. He successfully found a replacement new Isotherm 40ltr calorifier (quite a feat in

Tahiti that was locked down with the Covid-19 virus at the time) and installed it in May 2020 (see series of pictures below). In the

end, the repair was a simple "in" and "out" affair, requiring only a small amount of welding the new tank straps to the old tank's ones.

|

|

|

When we bought Ngahue IV, the boat had a Jabsco V-Flojet 5.0 water pump that operates without an external pressure tank. On the Web Hallberg-Rassy discussion forum (see Links page) there have been mixed and critical reviews of such a set-up. Most of the time our system worked okay; but in 2022, we decided to revert to the old-fashioned set-up of a heavy duty Jabsco water pump linked to an 8ltr expansion tank. Yes, you're often better off sticking to the traditional ways. Christoph Rassy, for one would wholeheartedly agree!!

Our boat came with double charcoal filters fitted by the Yard. On the HR53, the previous owner, a man of immense strength in his arms and

hands had tightened them to such an extent that we never succeeded in opening them to replace the filter elements inside. This gave us an

excellent excuse to order two completely new filters from Mellie Rassy at HR Parts. They were duly fitted, and changing filters is a very

simple job! Seen here with the feed pump from the watermaker installed underneath them. Seen here with the feed pump from the watermaker

installed underneath them. When we are not in a North-European marina, we view pontoon water with a suspicious eye and all water goes through

a 20 micron paper filter first.

When looking around for a watermaker for the boat - we wouldn't like to die of thirst in the middle of an ocean

surrounded by sea water - we wanted something that was solid and reliable. Our previous Hallberg-Rassies 37

& 43 both had US-made Spectra watermakers on board, operating on 12 volts. The one on the 37 was 'owner-installed' (i.e. by me);

the one of the 43 was Yard-fitted (i.e. by HR). Most watermakers in sailing boats operate with a reverse osmosis process, i.e.

pumping seawater through a fine membrane under very high pressure in order to remove salt and other impurities. This

system requires a lot of energy and typically discards two to three times the quantity of water produced overboard

as a reject-saline solution… After careful consideration, we opted for a technologically relatively simple watermaker

produced by the German company

Aquatec.

Their AC/150 model, which we opted for, comes in a modular package. The advantage is that this allowed us to install

the various parts of the watermaker around the aft cabin, the aft heads and the aft wall of the engine room.

It is then that you realise how "small" a Hallberg-Rassy 53 really is... Our membranes, for instance, would only fit (just!!)

under the two top cupboards hanging over the seat in the aft cabin (see picture; Leon Schulz helpfully suggested mounting the

membranes under the saloon settee; but we opted to keep this space for storage of food and boat spares). In order to get the most

efficient and least energy-hungry solution, the watermaker runs on 230V AC, which is provided by our Westerbeke generator

(see above). Of course this begs the question of our total reliability on this unit to provide and adequate supply of 230V for

the watermaker - our inverter alone is not big enough! DC watermakers are getting much better, and perhaps we should have opted

for such a solution. However, the owner of Aquatec, Herr Joachim Matz, with whom we had a loooooooooooooooooong conversation

during the BOOT Düsseldorf 2016 boat show was quite adamant. So the 230V route was our chosen path... At full throttle the unit

can produce a lot more than its rated 150 liters of water per hour but we try to keep production at about 150 ltr/hr. It requires

about 10-15 liters of fresh water to flush out the whole system at the end of use and requires about 10 amps electricity from our

generator (about a third of its capacity). We estimate that the watermaker should be run for an average of about 2 hours every

3-4 days. Aquatec watermakers have no electronics in them: in truth, there are only three electric switches as well as two electric

motors in the whole system! The individual parts that suffer most from wear and tear (notably the electric pumps) are Belgian and

German made and fully tested for an impeccable track record (and we have a spare for the smaller of the two pumps).

As already stated, our main problem with this unit, when we started fitting the various parts of the watermaker

into the boat, was the sheer length of the two tubes containing the membranes. After much looking around, we

found that we needed to install them in a visible (though not too invasive) place under the starboard cupboards

in the aft cabin. Readers can be the judge of whether we succeeded... Fortunately they are white and reasonably

decorative and don't intrude in the furnishings of our aft cabin too much... In true Hallberg-Rassy production

style, we mounted key elements of the watermaker on grey wooden boards (which we made up in the comfort of our

home in Brussels - most of the work was done over the winter 2016/17, and although the boat was "inside", you could

hardly call the engine room an inviting environment to work in). In the Yard, these boards are then simply screwed into

place and interconnected once the worker returns to the boat - it's an easier way of working. Pictured here one of

those boards with all the primary filters... These are sited in the aft end of the engine room and do not impinge

too much on the space available there. You can still quite comfortably walk (or crawl) into the engine room to work

around the main engine and the generator without getting too caught in equipment... A refinement we introduced after

a year of working with the watermaker was to give it its own dedicated through-hull and seacock. The idea is to avoid any

air bubbles getting into the high-pressure pump, which apparently can play havoc inside the pump mechanism!

As already stated, our main problem with this unit, when we started fitting the various parts of the watermaker

into the boat, was the sheer length of the two tubes containing the membranes. After much looking around, we

found that we needed to install them in a visible (though not too invasive) place under the starboard cupboards

in the aft cabin. Readers can be the judge of whether we succeeded... Fortunately they are white and reasonably

decorative and don't intrude in the furnishings of our aft cabin too much... In true Hallberg-Rassy production

style, we mounted key elements of the watermaker on grey wooden boards (which we made up in the comfort of our

home in Brussels - most of the work was done over the winter 2016/17, and although the boat was "inside", you could

hardly call the engine room an inviting environment to work in). In the Yard, these boards are then simply screwed into

place and interconnected once the worker returns to the boat - it's an easier way of working. Pictured here one of

those boards with all the primary filters... These are sited in the aft end of the engine room and do not impinge

too much on the space available there. You can still quite comfortably walk (or crawl) into the engine room to work

around the main engine and the generator without getting too caught in equipment... A refinement we introduced after

a year of working with the watermaker was to give it its own dedicated through-hull and seacock. The idea is to avoid any

air bubbles getting into the high-pressure pump, which apparently can play havoc inside the pump mechanism!

The Galley

The galley on Ngahue IV is situated to starboard, as you descend the main hatch and stairs. This is a pretty standard lay-out on many boats, including Hallberg-Rassies. Increasingly though, on the bigger Hallbergs, galleys have been placed more recently in the walk-through to the aft cabin. The advantage of our set-up is, we find, that the cook is firmly wedged into a very safe U-shaped galley and can work reasonably safely at sea (as can be seen on some of our You-Tube videos). The cook remains visible to people in the cockpit, and can hand up mugs and plates from the safety of the U-shaped galley. During our first 15,000M sailed with the boat we discovered two issues really. The first issue was the fridge, which is a top-opening unit, set in a corner of the galley. As described in more detail below, we needed to "un-improve" the fridge by stripping out the insalubrious layers of extra insulation that the previous owner had added. We then discovered that the fridge is actually a VERY BIG BOX and that you need long and flexible arms (the kind of arms you'd expect from a cross between a gorilla and an octopus) to be able to reach for the food that is stowed in the lower recesses of it. We've half solved the issue by using plastic baskets with stiff high handles to lift things out of the fridge. The second issue was our Force 10 gas cooker. The pan holder on it was the wrong design, so that when the cooker swung around in a seaway, the knobs on the pan holder knocked against the galley working surface and flew off. After studying a gas cooker for sale on Tortola, we discovered that Force 10 also makes another and better designed pan holder - one with an off-set built in (see photo below). We ordered it and fitted it: problem of flying pots and pans solved! One really wonders why this particular pan holder model wasn't fitted on our cooker in the first place! The oven burst into flames late 2022 and was replaced by an identical, new unit in early 2023! We insisted on the 'other' type of pan holder to avoid a repeat of the earlier issue. Generally speaking Force 10 cookers are pretty solid and certainly up to 'live-aboard' standards...

Refrigeration

As already described on several occasions throughout this website, the previous owner had "improved" the energy efficiency of the fridge and freezer on Ngahue IV by gluing additional sheets of polystyrene to the walls of the freezer and subsequently gluing sheets of thin perspex over the polystyrene. Referring to the series of pictures below of the "before" situation and you will notice how much space was used up by this method. The series of 4 photos shows the work as we did it in the freezer - and the last photo on the right shows a not much better situation in the fridge.

Here a series of photos taken during the removal process of the extra layers of insulation. If you want to see the final and clean result, please turn to the "Preparing for the ARC" - the difference is quite impressive... Suffice it to say that never in 4 years of live-aboard that we had any food-poisoning trouble from our fridge or freezer!

Because the previous owner hadn't sealed the joins between his perspex very well, you can see how water, condensation and general muck had seeped into the bottom of the fridge and freezer. As a result, both smelled really bad. We dread to think what a laboratory analysis of the brown water would have revealed. Instant death, no doubt... Gordon Ramsay would have closed us down in a wink, as he does sometimes in his "Hell in the Kitchen" programmes.

Pictured here is the compressor for the fridge

which is air-cooled and was placed, by the previous owner, under the floorboards in the saloon area. We have left it there, but removed the

compressor for the freezer (part of it just visible to the right in the picture) which was placed next to it as the whole cooling system for

the freezer needed to be removed anyway. We now needed to look around for alternatives and after some hunting around, opted for an

Indel-Webasto (Isotherm) seawater cooled freezer unit. Interestingly

enough, all manufacturers seem to use Danfoss compressors for their fridges and freezers. Our model came with a Danfoss BDF80 compressor and a

huge cooling plate (130cm in length) and is part of their Magnum range. Furthermore, the compressor is cooled by seawater which is circulated

around the compressor thanks to a dedicated water pump. The system is particularly recommended for boats requiring a lot of "cold power" in the

tropics - exactly what we need for our freezer around the equator… Fortunately, after looking around the engine room, we found - quite by chance

- the original water inlet & outlet for the 1995 Frigoboat cooling system that Hallberg-Rassy had installed for the first owner. We re-used the

inlet, which saved me from drilling an extra hole in the boat - always a tricky business... Quite by chance, and some months after installing

the new compressor, we discovered that the old hoses from the Frigoboat era were about to burst, which would indeed have sunk the boat, as all

these connections are helpfully situated under the waterline and in places that are VERY difficult to inspect! A new hose was quickly fitted

(one technician keeping his finger on an open hole in the pipe, while his colleague quickly went to the local chandlery to get a new hose!) and

the installation made safe again! During our winter 2018/19 refit in Bruinisse, all of this was removed and new Trelleborg hoses and seacocks

fitted to make for a 100% safe installation.

Pictured here is the compressor for the fridge

which is air-cooled and was placed, by the previous owner, under the floorboards in the saloon area. We have left it there, but removed the

compressor for the freezer (part of it just visible to the right in the picture) which was placed next to it as the whole cooling system for

the freezer needed to be removed anyway. We now needed to look around for alternatives and after some hunting around, opted for an

Indel-Webasto (Isotherm) seawater cooled freezer unit. Interestingly

enough, all manufacturers seem to use Danfoss compressors for their fridges and freezers. Our model came with a Danfoss BDF80 compressor and a

huge cooling plate (130cm in length) and is part of their Magnum range. Furthermore, the compressor is cooled by seawater which is circulated

around the compressor thanks to a dedicated water pump. The system is particularly recommended for boats requiring a lot of "cold power" in the

tropics - exactly what we need for our freezer around the equator… Fortunately, after looking around the engine room, we found - quite by chance

- the original water inlet & outlet for the 1995 Frigoboat cooling system that Hallberg-Rassy had installed for the first owner. We re-used the

inlet, which saved me from drilling an extra hole in the boat - always a tricky business... Quite by chance, and some months after installing

the new compressor, we discovered that the old hoses from the Frigoboat era were about to burst, which would indeed have sunk the boat, as all

these connections are helpfully situated under the waterline and in places that are VERY difficult to inspect! A new hose was quickly fitted

(one technician keeping his finger on an open hole in the pipe, while his colleague quickly went to the local chandlery to get a new hose!) and

the installation made safe again! During our winter 2018/19 refit in Bruinisse, all of this was removed and new Trelleborg hoses and seacocks

fitted to make for a 100% safe installation.

Our fridge cooling system has therefore essentially remained unchanged, despite Leon Schulz's advice to change both compressors to Webasto's Magnum range. This is what he has done on his boat, the Regina Laska. Our reasoning is that at the moment, the fridge works too well and even at the highest temperature manages to freeze our vegetables and fruit to pulp and transforms our soft drinks into ice. Our hope that as the fridge volume has increased with the removal of all that internal insulation, the effect of the evaporator will be less, and consequently achieve a "normal" fridge temperature as a result proved to be in vain. Yes, in the tropics it proved to be less efficient than a water-cooled unit; but we hope our additional external insulation and tweaks to the refrigeration system that we have in mind for the future will keep consumption within bounds. Both units require 2 to 2.5 Amps (at 24V) to operate, and use about 30 Ah over a 24-hour period in the tropics. We have enough power-generation possibilities on board to cover the energy hungry requirements of our cooling appliances!

As we were approaching Tahiti, the freezer compressor started becoming quieter and quieter and once in Marina de Papeete became completely silent! On the one hand, this was good news, as we could sleep in peace. Until, one day, I touched the compressor and nearly burned my fingers... It transpired that the seawater pump had stopped working altogether and the freezer was operating without any cooling system of its own. Fortunately Luc Vacher of Polymarine Solutions in Papeete managed to find a replacement relay and a new seawater pump to repair our freezer. The old seawater pump had corroded quite badly (see picture on the left) as the result of a leak - when putting everything back together, we have tried to ensure that the various components might avoid causing a serious new leak in future. The two other pictures show the repair in progress and the cleaned up compressor readily working again afterwards.

After a few months in Tahiti, the fridge also stopped working: it required a new electronic regulator: the compressor and gas was all in order; but the continuous heat in Tahiti had been too much for the controlling electronics... This was one of the things that we found as the Covid-19 pandemic led to us staying put in Papeete marina for more than 8 months, namely that systems operating in the tropical heat of a constant 28-30°C are not built for this and just pack up after some time. Three photos show Luc Vacher, our 'Mr Cold' working on the fridge compressor which is in the bilge; the new manual bilge pump replacement (situated under the floor next to the chart table); and the water pump replacement for the freezer compressor (the membrane on the old pump broke).

|

|

|

|

|

|

When reading through reviews on Mr Vacher's work, many passing-through yachtsmen were damning of him. Very unjustifiably we found! He was excellent at his job, dedicated, punctual and hardly expensive. He certainly has our 100% stamp of approval.

One final comment on our fridge and freezer... Strangely enough, the lid of the freezer is only half as thick as the lid of our fridge and very easy to lift (the fridge lid weighs a ton and needs lots of strength to lift). Funny how Hallberg-Rassy didn't put the same amount of insulation around the freezer, which has to deal with far lower temperatures and generates much higher potential heat losses than the fridge!!!

Suffice it to say that we carry multiple spares for each of the pumps on board and for various sensitive electronic parts. Because we have streamlined our equipment to use the same or similar pumps, we do have a lot of 'capacity' with us to replace material when it breaks down - which it invariably does when you're gone for long-term cruising. Another trick is to know what you have on board as spares - which requires a solid administration...

Keeping cool inside the boat

Inside the boat, we have installed 8 fixed Caframo 24-volt ventilator fans: 3 in the saloon, 2 in the aft cabin, and 2 in the fore peak and

1 in the small fore cabin. After my (hot) experience of working in the engine room in the tropics, we added a Hella fan in the engine room and

also have a mobile Caframo fan on a wooden pedestal which we use where it is most needed - after all, it gets very hot 'inside' in the tropics.

All fans operate at three speeds, the lowest of which is reasonably inaudible (and provided the fan is not next to your ears, can be quietly

slept next to). Speeds 2 & 3 progressively make more noise, but of course do shift more air-mass.

Usually, larger Rassies have air-conditioning on board, with up to 3 units cooling the aft cabin, the saloon and the forepeak. But airco units

require a lot of energy (which is why you have a big generator on board, the Yard would say...). They also require extra holes in the hull to

let seawater in and out to cool the airco units. From what I read, you need either a very, very, very large (preferably Lithium) battery bank,

or a generator running most of the time to keep the air-conditioning going (or special shorepower in the Caribbean & elsewhere). We're interested

in none of these aspects, and have therefore opted for the "poor man's airco": open windows and hatches with the Caframo ventilators to circulate

whatever (cool) air comes into the boat. Experience in the Caribbean and most of the Pacific (up to 30°C with lots of humidity) is that this

solution is pretty much OK actually... It only becomes really hot inside in 30°C+ and the sun beating on the boat all day long... Adding biminis

and large sheets to keep the sun off the windows works very efficiently too... The only flea in the ointment are tropical showers: you need to watch

your windows to avoid getting the boat's interior wet. Then again, wet things do dry very quickly in the tropics! And we did go long-term sailing

to escape the cold weather in Europe, no??? Pictured here the two Caframo fans in the aft cabin.

Usually, larger Rassies have air-conditioning on board, with up to 3 units cooling the aft cabin, the saloon and the forepeak. But airco units

require a lot of energy (which is why you have a big generator on board, the Yard would say...). They also require extra holes in the hull to

let seawater in and out to cool the airco units. From what I read, you need either a very, very, very large (preferably Lithium) battery bank,

or a generator running most of the time to keep the air-conditioning going (or special shorepower in the Caribbean & elsewhere). We're interested

in none of these aspects, and have therefore opted for the "poor man's airco": open windows and hatches with the Caframo ventilators to circulate

whatever (cool) air comes into the boat. Experience in the Caribbean and most of the Pacific (up to 30°C with lots of humidity) is that this

solution is pretty much OK actually... It only becomes really hot inside in 30°C+ and the sun beating on the boat all day long... Adding biminis

and large sheets to keep the sun off the windows works very efficiently too... The only flea in the ointment are tropical showers: you need to watch

your windows to avoid getting the boat's interior wet. Then again, wet things do dry very quickly in the tropics! And we did go long-term sailing

to escape the cold weather in Europe, no??? Pictured here the two Caframo fans in the aft cabin.